NETWORK GROUP, s.r.o.

Address: Olomoucka 91, 627 00 Brno

Contact: www.nwg.cz, sfo.nwg.cz

Founding: 1995

Number of employees: 50

Since its establishment in 1995, NETWORK GROUP operates as a distributor of structured and optical wiring system. In 2000, it expanded its activities into the area of printed circuit boards. Apart from its business and production activities, the company founded its research and technological department for projects, research and development of advanced optical fiber elements which are used especially in advanced industrial applications.

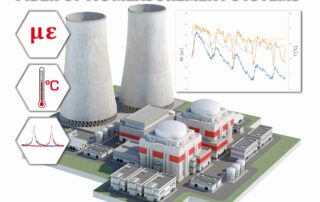

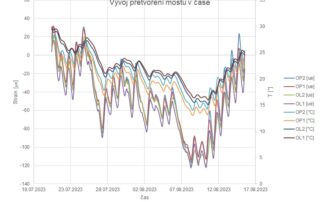

NETWORK GROUP, department of special fibre optics, is focused on the in-house design, development and production of versatile sensor systems based on FBG (Fibre Bragg Grating), using a team of specialists and high-tech equipment. The main area of interest is the measurement and monitoring of critical infrastructures where deformation, strain and temperature profiles or vibrations are required. Typical applications include Bridges, Nuclear Power Plants, Silos for storage of bulk or chemical materials, advanced industrial applications and Railway traffic.

Main activities:

- Complex sensors systems for measurement and monitoring of temperature, deformations, strain, vibrations, etc.

- Structure health monitoring

- Systems for strain and temperature measurement of containment for nuclear power plants

- Temperature measurement in industrial and chemical silos and other special applications

- Measurement, monitoring and diagnostics of reinforced concrete structures, especially bridges.

- Railway monitoring

- Custom turnkey measurement systems

Services:

- Turnkey measurement and monitoring systems

- Measurement, monitoring and diagnostics of bridges

- Systems for strain and temperature measurement of containment for nuclear power plants

- Temperature measurement in industrial and chemical silos

- Specialized temperature monitoring

- Railway monitoring

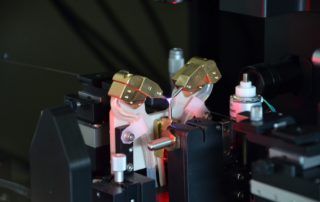

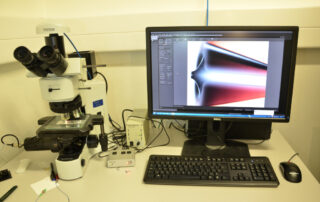

- Femto second laser micromachining system:

- Surface micro and nano structuring

- Engraving

- Micro drilling

- Refractive index modification inside bulk of material

- Dicing and cutting brittle materials

- Micromachining of rotary symmetrical structures

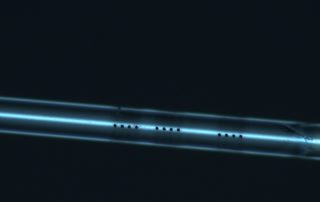

- Advance fiber glass processing:

- Splicing of fibers with different diameters (125 µm up to 2 mm)

- Splicing of PCF (Photonic-crystal fibers)

- Tapering – up to 85 mm, symmetrical / asymmetrical

- Endcaping

- Splicing of GRIN lenses

- Electronic production

- PCB assembling

- SMT + THT technology

- Cabling systems

- Optical and metallic cables

- Passive components for telecommunication

Specialized equipment:

- Femtosecond laser

- Large diameter splicing system

- Excimer UV laser for FBGs production

- Hot-air stripper for acrylate primary coating

- Acrylate and polyimide recoater

- Calibration baths

- LTCC (low-temperature co-fired ceramic) workshop

- Active and passive wavelength references

- PCB assembling division

- Prototype workshop